KremGuard

Fire protection redefined

Composite materials have become essential to mobility, enabling a range of innovations. In addition to lightweight properties, safety is the top priority when it comes to aircraft, rail or electric cars. A fire can have catastrophic consequences, in an emergency, every second counts for saving lives. The materials used in the aerospace, rail and automotive industries must therefore meet strict requirements for Fire, Smoke & Toxicity (FST) i.e. flammability, smoke density and smoke toxicity.

Our latest composite innovation, the epoxy resin-based prepreg system KremGuard, redefines the standards for low flame propagation, low smoke development and low toxicity.

KremGuard

You can have confidence in this:

- Meets the highest FST fire protection requirements – flammability,

heat release and smoke development are reduced to a minimum - Excellent mechanical properties

- Free from phenol, formaldehyde and halogens

- Ideal choice for structural components and honeycomb sandwiches

- Homogeneous, non-porous surface

- Improved storability and shelf life compared to traditional phenolic systems

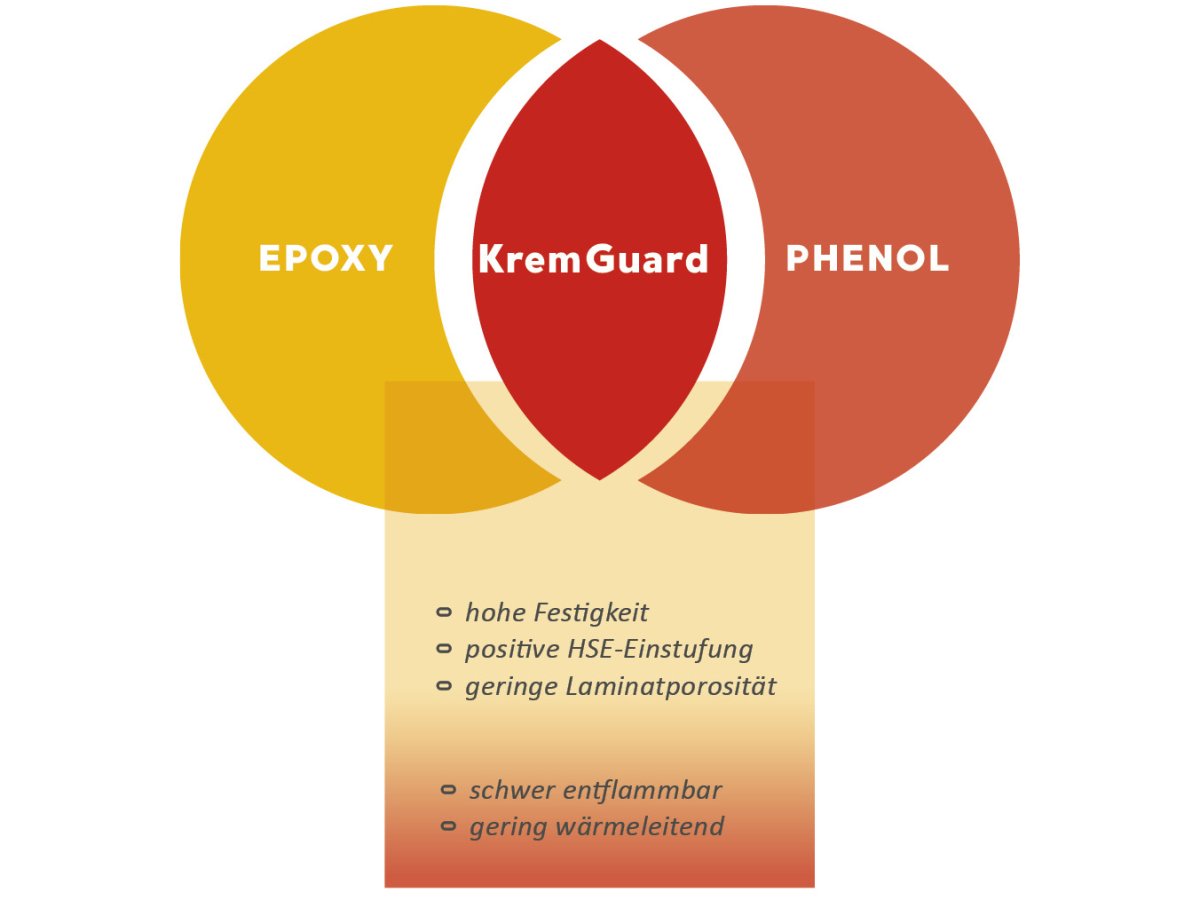

The best properties of epoxy & phenol

During development, we combined the best properties of epoxy and phenol. The result: KremGuard.

Above all, KremGuard fulfills high fire and heat protection requirements. Even in complex composite structures, KremGuard is non-flammable, conducts little heat and generates hardly any smoke or toxic gases. These properties are achieved without the use of phenols, formaldehyde and halogens that harm our health and the environment. In addition, it has excellent mechanical properties and can be easily processed, even in the case of complex component shapes. The homogeneous, nonporous

surface can easily be coated, and integrated into your design. This makes KremGuard the optimum basis for use in interiors, exteriors, structural components and sandwich structures. Moreover: KremGuard outperforms existing phenolic systems at room temperature in terms of storability and shelf life.

KremGuard therefore sets a new standard for safety in the air, by rail and in terms of battery-operation on the road.

Standards

The strict safety and quality standards that are a prerequisite for applications in aircraft and trains are guaranteed with KremGuard: FAR 25, AIMS, AITM and EN45545 up to the highest classification HL3. In addition, KremGuard has been subjected to comprehensive testing with the UL Torch & Grid test. The result: KremGuard meets stringent fire protection requirements in a variety of applications, including automotive components and battery housings.

Aviation

- FAR 25

- AIMS (Airbus Industries Material Specification)

- AITM (Airbus Industries Test Method)

Railway

- EN 45545 HL3, R1, R7, R17

Industry

- UL-94 V0

KremGuard

Our portfolio:

- Prepregs

- Rigid laminates / laminate panels

- Sandwich panels and components with a honeycomb structure

- Components

KremGuard FST-Performance

| Test/Property | Unit | Result | Requirement | Standard |

|---|---|---|---|---|

| Burn length (12 s ignition time) | mm | 34 | 203 | AITM 2.0002-B |

| After flame time (12 s ignition time) | s | 0 | 15 | AITM 2.0002-B |

| Drips (12 s ignition time) | yes/no | nein | AITM 2.0002-B | |

|

|

mm | 58 | 152 | AITM 2.0002-A |

|

|

s | 0 | 15 | AITM 2.0002-A |

| Drips (60 s ignition time) | yes/no | nein | AITM 2.0002-A | |

| Smoke density | Ds | 6 | 200 | AITM2-0007 |

| Heat release rate max | kW/m² | 40 | < 65 | AITM2-0006 |

| Heat release - 2 min | kW*min/m² | 45 | < 65 | AITM-0006 |

| Toxicity Test | HCN (ppm) | 4 | 150 | AITM3-0005 |

| Toxicity Test | CO (ppm) | 121 | 1000 | AITM3-0005 |

| Toxicity Test | NOx (ppm) | 11 | 100 | AITM3-0005 |

| Toxicity Test | SO2 (ppm) | 10 | 100 | AITM3-0005 |

| Toxicity Test | HF (ppm) | 0 | 100 | AITM3-0005 |

| Toxicity Test | HCI (ppm) | 0 | 150 | AITM3-0005 |

The values given are typical values based on specific test specimens. Technical modifications reserved.

KremGuard mechanical values

| Test material | Test | Result in N/mm² | Requirement in N/mm² | Standard |

|---|---|---|---|---|

| Unconditioned laminate | Flexural strength - warp direction | 539,8 | >450 | ISO 178 |

| Unconditioned laminate | Flexural strength - weft direction | 467,6 | >360 | ISO 178 |

| Unconditioned laminate | E-Modul - warp direction | 23188 | >19000 | ISO 178 |

| Unconditioned laminate | E-Modul - weft direction | 21653 | >17000 | ISO 178 |

| Laminate in Skydrol 500 h | Flexural strength - warp direction | 585 | >360 | ISO 178 |

| Laminate in Skydrol 500 h | E-Modul - warp direction | 24104 | >17000 | ISO 178 |

| Laminate in destilled water 500 h | Flexural strength - warp direction | 548 | >370 | ISO 178 |

| Laminat in destilled water 500 h | E-Modul - warp direction | 23551 | >17000 | ISO 178 |

| Honeycomb LN 29967 A4 9,4 | Flexural strength - warp direction | 1040 | >700 | AITM 1-0018 |

The values given are typical values based on specific test specimens. Technical modifications reserved.

Applications of KremGuard

KremGuard can be used for robust walls, frames, doors and air conditioning ducts that effortlessly withstand everyday stresses. KremGuard combines long-lasting performance with aesthetic design.

KremGuard is suitable for bodywork and design elements. With coating it can withstand climatic conditions.

KremGuard enables the production of robust, light-weight structural components with exceptional strength.

Downloads

KremGuard - Fire and Flame Safety

Epoxy prepreg system for maximum fire protection